Video Showcase

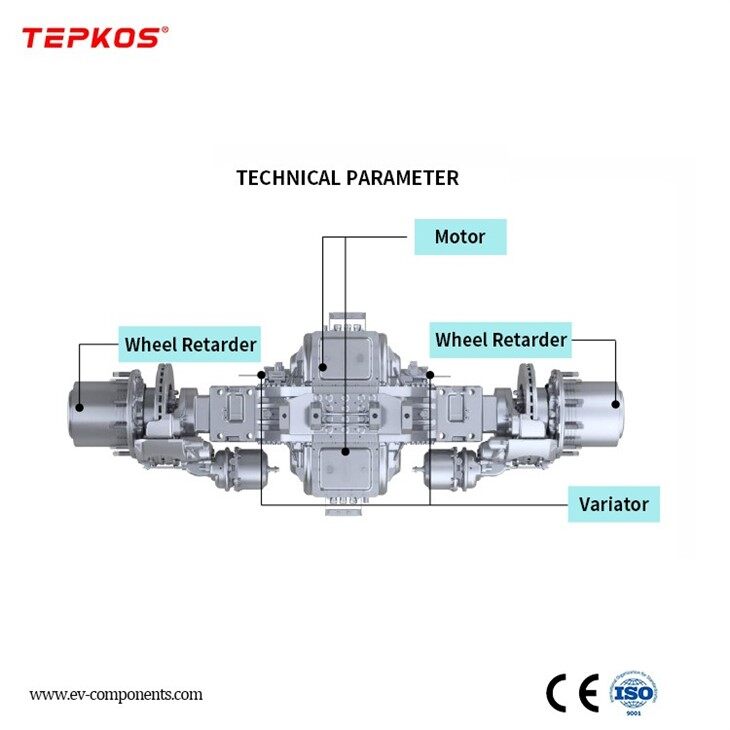

Electric Drive Axle for Trucks: EA5000N 13/16T Distributed Solution

For fleet operators and truck manufacturers, the shift to electric powertrains isn't just about compliance-it's about building a more efficient, cost-effective, and sustainable future. Our EA5000N electric drive axle for trucks is our answer to the unique challenges of heavy-duty electrification: how to maximize range without sacrificing power, reduce weight without compromising safety, and simplify integration without limiting customization.

Engineered for Heavy-Duty Demands

This EA5000N isn't just another electric drive axle for trucks-it's a system designed from the ground up to meet the rigors of long-haul transport, construction, and logistics. Here's how the numbers translate to real-world performance:

| Parameter | Unit | EA5000N Specification |

|---|---|---|

| Motor Type | - | Permanent Magnet Synchronous Motor (PMSM) |

| Peak/Rated Power | kW | 2×180 / 2×80 |

| System Output Torque | N·m | 50,000 |

| Rated Axle Load | kg | 13,000 / 16,000 |

| Protection Class | - | IP68 (1.5m water immersion for 60 minutes) |

| Gear Ratio | - | 49.4:1 / 15.3:1 |

What do these specs mean for your operation? This dual PMSM motors in our electric drive axle for trucks deliver instant torque for steep inclines, while the IP68 rating ensures reliability in rain, mud, or snow-critical for construction and off-road applications. Our 50,000 N·m torque output outperforms many central drive systems, making it ideal for 4×2 tractors hauling maximum loads.

Why Fleet Operators Choose Our Electric Drive Axle for Trucks

We designed the EA5000N to solve three core pain points for truck electrification: range anxiety, payload limitations, and integration complexity. Here's how we deliver on each:

Extend Payload Range

Traditional central drive systems add weight and bulk, forcing compromises between battery size and payload. Our distributed electric drive axle for trucks eliminates the need for a separate motor and transmission, reducing overall vehicle weight by 300kg. That extra capacity lets you add more battery cells-or increase payload-without sacrificing performance.

Safety You Can Trust in Any Condition

Heavy trucks need reliable traction-especially in wet or icy conditions. The EA5000N's dual-motor design and advanced gear-shifting control strategy ensure uninterrupted power delivery during gear changes, while the built-in Electronic Anti-Slip Regulation (EASR) prevents wheel spin on slippery roads. For operators in regions with harsh winters, this isn't just a feature-it's a necessity.

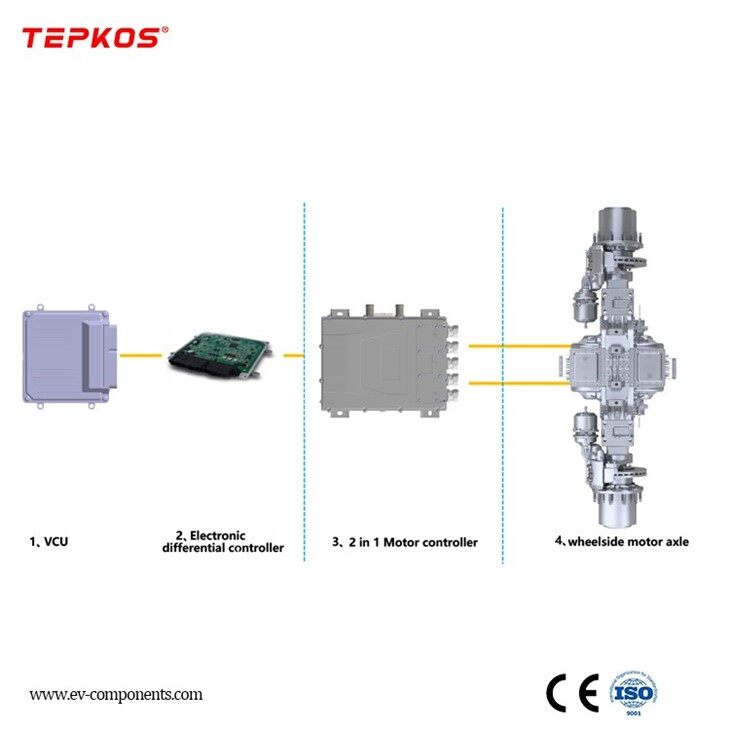

Simplify Integration, Maximize Flexibility

OEMs and upfitters hate one-size-fits-all solutions. The EA5000N's modular design fits seamlessly into existing chassis, with optional PTO (Power Take-Off) units for auxiliary systems like hydraulics. We also offer custom gear ratios to match your specific application-whether you need high torque for construction or high speed for highway hauling.

Designed for Your Fleet's Unique Needs

Our EA5000N electric drive axle for trucks isn't a one-size-fits-all solution. We offer configurations to match your vehicle type, application, and regional regulations:

| Vehicle Type | Axle Load | Gear Ratio Options | Key Applications |

| 4×2 Tractors | 13,000kg | 49.4:1 (low speed, high torque) | Long-haul freight, regional delivery |

| 6×4 Dump Trucks | 16,000kg | 15.3:1 (high speed, balanced torque) | Construction, mining, waste management |

| 8×4 Concrete Mixers | 16,000kg | Custom ratios available | Heavy-duty construction, urban transit |

Answers to Your Electric Drive Axle Questions

How does an electric drive axle for trucks differ from a central drive system?

Central drive systems place the motor and transmission in a single unit, often requiring a driveshaft to power the axles. Our distributed electric drive axle integrates the motor directly into the axle, eliminating the driveshaft and reducing weight. This design also improves weight distribution, which enhances stability and reduces the risk of rollovers-especially important for heavy loads.

Can the EA5000N be retrofitted into existing diesel trucks?

Yes-we've worked with several upfitters to convert diesel fleets to electric using the EA5000N. The modular design makes integration easier than many central drive systems, though retrofitting does require chassis modifications. Our team provides detailed engineering support to ensure a smooth transition.

What maintenance does an electric drive axle for trucks require?

Electric axles have far fewer moving parts than diesel powertrains, so maintenance is significantly reduced. We recommend inspecting the axle every 50,000km for fluid levels and wear, but most fleets report a 30-40% reduction in maintenance costs compared to diesel.

Contact Us for Pricing and More Information