Commercial vehicles operate in harsh environments: heavy payloads, frequent stops, and uneven roads. A recirculating ball type steering system addresses these pain points:

High Torque, Low Effort: The recirculating ball-and-nut mechanism generates up to 2000Nm of torque, making heavy trucks feel responsive.

Smart Assistance: An electric motor adjusts power based on speed and load, reducing driver fatigue during long hauls or tight maneuvers.

Seamless Integration: Designed to fit existing vehicle architectures, it supports features like ADAS and OTA updates without major redesigns.

For vehicle manufacturers, this means a solution that balances performance, cost, and time-to-market-critical for staying competitive in fast-evolving markets.

Core Components: Built for Reliability

Every part of our recirculating ball type steering system is engineered for commercial toughness:

Angle Sensor:

Tracks steering wheel position with ±0.5° accuracy, ensuring the motor delivers precise assistance.

ECU (Electronic Control Unit):

Runs adaptive algorithms to adjust power based on speed, temperature, and load. It supports CAN/CANFD communication, linking seamlessly to your vehicle's network.

Electric Motor:

TRION X-EPS 915 uses a brush motor (cost-effective for light loads), while the X-EPS 2000 uses a brushless motor (more efficient for heavy-duty cycles).

Ball Screw Assembly:

TRION recirculating ball screw minimizes friction, ensuring smooth operation over hundreds of thousands of cycles.

Product Introduction: How It Works

At its core, TRION recirculating ball type steering system uses a ball-and-nut assembly to convert rotational motion into linear force, amplified by an electric motor. Here's what sets our two models apart:

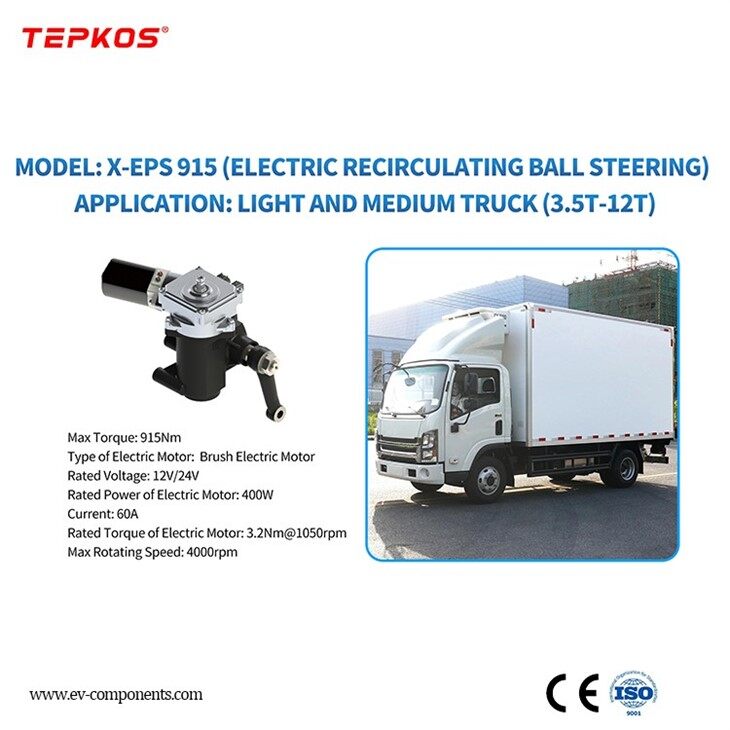

X-EPS 915 (Brush Motor)

Torque: 915Nm (ideal for light-duty trucks/vans).

Motor: Brush electric motor (400W, 60A) for cost-effective reliability.

Use Case: Perfect for 3.5T–8T vehicles like delivery vans or light cargo trucks.

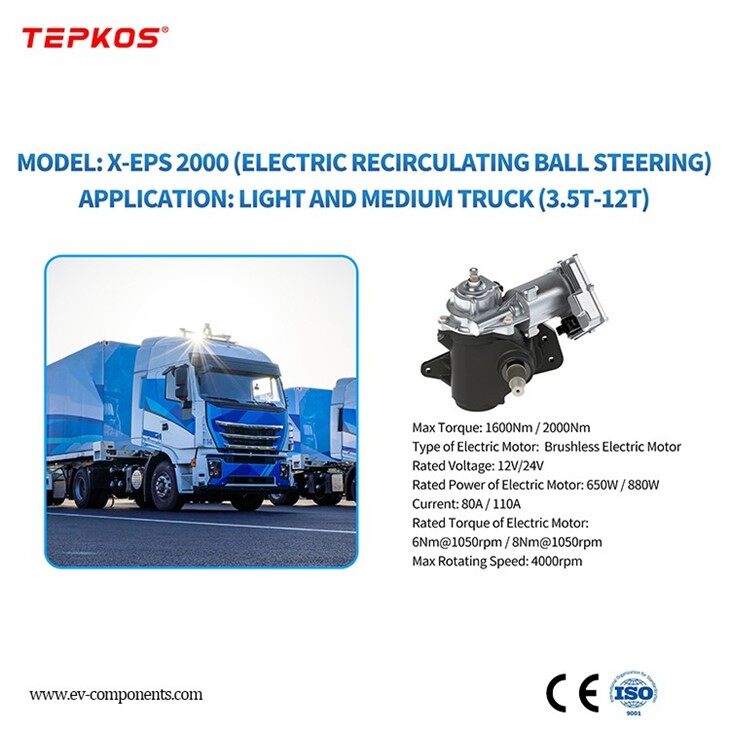

X-EPS 2000 (Brushless Motor)

Torque: 1600–2000Nm (built for heavy loads).

Motor: Brushless electric motor (650W–880W, 80A–110A) for efficiency and durability.

Use Case: Suited for 8T–12T trucks, including specialty vehicles like refrigerated carriers.

Parameters of Recirculating Ball Type Steering System

|

Max Torque: |

915Nm |

1600Nm/2000Nm |

|

Type of Electric Motor: |

Brush Electric Motor |

Brushless Electric Motor |

|

Rated Voltage: |

12V/24V |

12V/24V |

|

Rated Power of Electric Motor: |

400W |

650W/880W |

|

Current: |

60A |

80A/110A |

|

Rated Torque of Electric Motor: |

3.2Nm@1050rpm |

6Nm@1050rpm/8Nm@1050rpm |

|

Max Rotating Speed: |

4000rpm |

4000rpm |

Product Functions: Beyond Basic Steering

The system enhances safety and comfort with smart features:

Speed-Sensitive Assistance:

Lighter at low speeds and stiffer at high speeds.

Active Return-to-Center:

Helps the steering wheel self-center after turns, reducing driver fatigue.

Temperature & Load Compensation:

Adjusts power in extreme conditions or uneven loads, ensuring consistent performance.

ADAS Compatibility:

Supports Level 2+ features like lane keep assist, communicating with vehicle sensors.

Product Advantages: Why It Stands Out

Wide Torque Coverage:

TRION X-EPS 2000 handles up to 2000Nm, covering 1500–2000Nm for diverse applications.

Future-Proof Design:

OTA updates and cybersecurity encryption keep the system current with evolving tech.

Safety-Certified:

Meets international safety standards and national regulations, ensuring reliability.

Customizable Interfaces:

Works with various TAS sensors and protocols, integrating seamlessly into your design.

Product Applications: Where It Excels

This system thrives in commercial environments:

Light Trucks & Vans:

Delivery fleets and refrigerated trucks benefit from responsive steering and low-speed assistance.

Electric Commercial Vehicles:

Pairs well with electric drivetrains, optimizing energy use and supporting regenerative braking.

Special Vehicles:

Ambulances, utility trucks, and construction vehicles rely on high torque for precise maneuvers.

Production Manufacturing: Scaling Quality

Producing a reliable recirculating ball type steering system requires precision:

Automated Assembly: Robots handle critical steps (motor calibration, sensor alignment) to minimize errors.

End-to-End Quality Checks: Every unit is tested for torque, noise, and endurance before shipping.

Flexible Production: Small-batch prototyping for custom projects, plus high-volume lines for mass production.

Assembly line No. 1 (C-EPS)

Assembly Line II (RB-EPS)

Final Assembly Line III (R-EPS/DP-EPS)

ECU (Controller) Assembly Line (Sensor Assembly Line)

Reducer Flexible Assembly Line

EPS Brushless Motor Assembly Line

FAQ: Answers for Vehicle Manufacturers

Q1: How long does it take to integrate the system into our platform?

Most integrations take 8–12 weeks for standard setups. Custom modifications add 4–6 weeks, but our modular design minimizes chassis changes.

Q2: Can we customize the system for our specific vehicle?

Yes. We adjust torque ranges, motor specs, and even communication protocols. For example, we've modified the X-EPS 915's calibration for a client's low-speed delivery trucks in 10 weeks.

Q3: What support do you offer during production?

Our team provides on-site assistance for assembly line integration, calibration, and first-run optimization. We also share CAD models and simulation data to streamline your design process.

Q4: Do you have case studies of this system in similar commercial vehicle projects?

We've successfully deployed TRION recirculating ball type steering system in light trucks, delivery vans, and specialty vehicles. For example, one project reduced driver steering effort by 30% in fully loaded conditions while improving highway stability. While we can't share specific client names, we can provide anonymized performance data, test reports, or even arrange a benchmark comparison with your current steering solution.

Recirculating Ball Type Steering System For Commercial Vehicles

This recirculating ball type steering system isn't just a component-it's a partnership for building better commercial vehicles. By focusing on real-world challenges (payload, driver fatigue, future tech), we deliver a solution that OEMs can trust to perform, integrate, and evolve.